How it works

Collect - Shred - Inject

Collect:

To recycle plastic waste, it must be sorted (by type) and cleaned (without labels, dirt, ...). The idea behind Precious Plastic is to set up small and local recycling workplaces around the world. This way we can intercept the plastic waste before it becomes too difficult to sort and clean.

To collect local plastic waste, we need a few collection points and shops that are willing to clean and sort their plastic waste and, if possible, also serve as collection points.

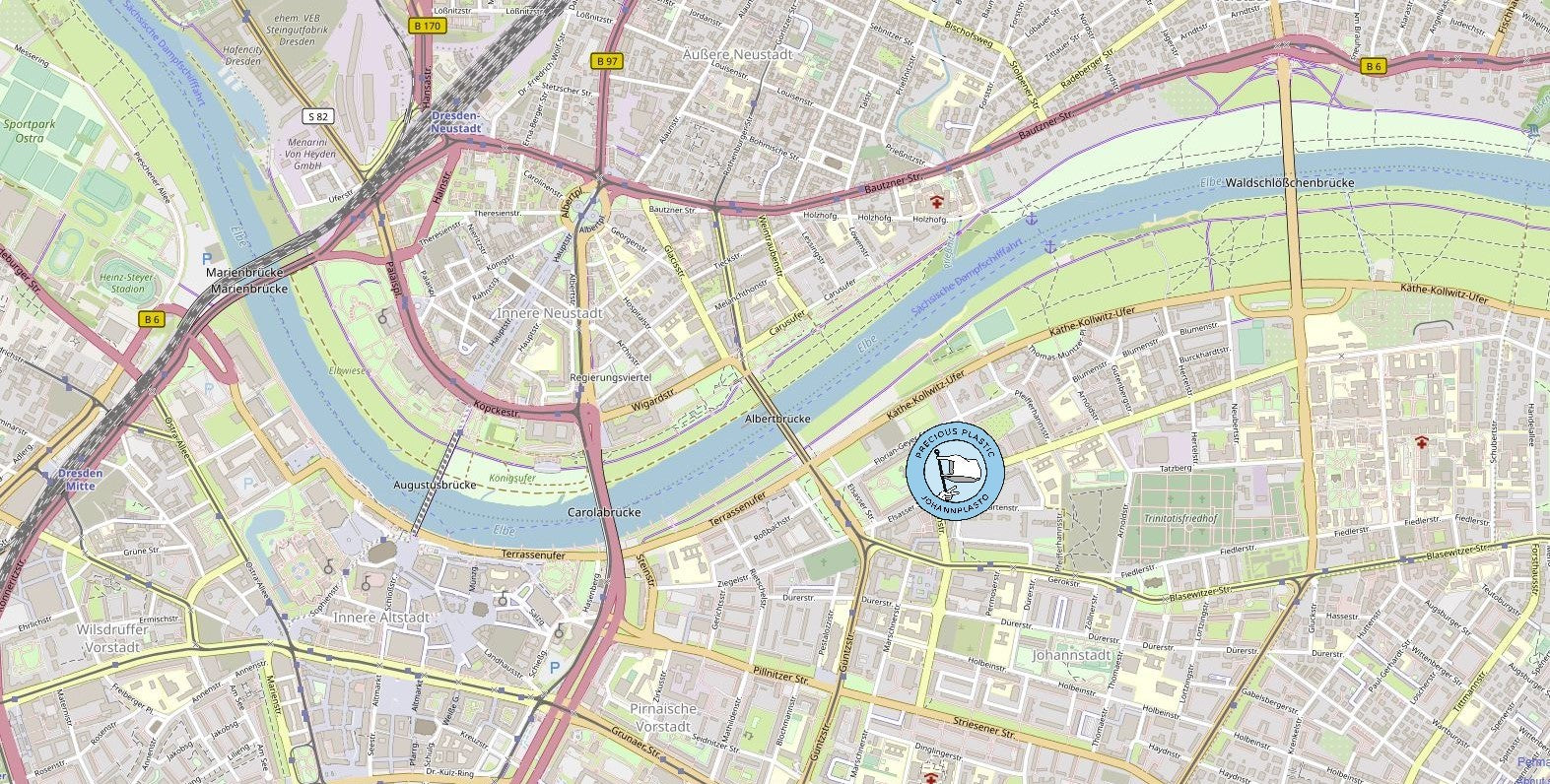

The local network for Johannplasto is shown on the map below. Get in touch if you want to open a collection point. If you want to drop off your clean and sorted plastic waste, get in touch with one of the collection points.

Shredding:

The basis for most plastic recycling processes is the shredding of sorted plastic waste into small granules. The Johannplasto Shredder can shred plastic waste up to 5 mm thick, does its job very quietly and rains down up to 5 kg of plastic granules (5 or 8 mm) per hour.

Let's shred plastic waste!

Inject:

The plastic, shredded into small granules, can now be filled into the injection machine. There, the plastic is heated to the desired temperature using hot spirals. The now liquid plastic can then be injected quickly and powerfully into the intended mold. The molds are usually made of milled steel or aluminum.

The process

-

Collect:

To recycle plastic waste, it must be sorted (by type) and cleaned (without labels, dirt, ...). The idea behind Precious Plastic is to set up small and local recycling workplaces around the world. This way we can intercept the plastic waste before it becomes too difficult to sort and clean.

The local network for Johannplasto is shown on the map below.If you would like to dispose of your clean and sorted plastic waste, please contact one of the collection points.

-

Shredding:

The basis for most plastic recycling processes is the shredding of sorted plastic waste into small granules. The Johannplasto Shredder can shred plastic waste up to 5 mm thick, does its job very quietly and rains down up to 5 kg of plastic granules (5 or 8 mm) per hour.

Let's shred plastic waste! -

Inject:

The plastic, shredded into small granules, can now be filled into the injection machine. There, the plastic is heated to the desired temperature using hot spirals. The now liquid plastic can then be injected quickly and powerfully into the intended mold. The molds are usually made of milled steel or aluminum.

-

Column

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.

-

-

Column

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.